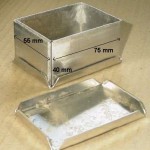

The main aim of sampling is to obtain soil samples in as undisturbed a state as possible. The process involves the careful use of Kubiena tins inserted into soil profiles, removed, sealed and bagged for transport to the lab.

The main aim of sampling is to obtain soil samples in as undisturbed a state as possible. The process involves the careful use of Kubiena tins inserted into soil profiles, removed, sealed and bagged for transport to the lab.

back in the lab samples are normally dried because for most purposes the resins used for impregnation are hydrophobic. This can be achieved by oven drying, air drying or by solvent exchange (acetone). The first two methods can be extremely detrimental to the soil structure causing shrinking and cracking, therefore the preferred method at Stirling is solvent exchange in the vapour phase, this ensure minimal disturbance to the sample.

detrimental to the soil structure causing shrinking and cracking, therefore the preferred method at Stirling is solvent exchange in the vapour phase, this ensure minimal disturbance to the sample.

The choice of resin for impregnation is determined by the intended use of the soil thin section slide. For ‘normal’ slides produced for standard microscopy and image analysis techniques the resin of choice is a polyester called crystic 7449. This resin is readily thinned by acetone and the curing time can be controlled easily by increasing or decreasing the amount of catalyst (methyl ethyl ketone peroxide, MEKP). An ‘accelerator’ can also be added to shorten the curing time. If the soil thin section slide is to be used in SEM or Microprobe analysis for example then the resin of choice is epoxy (Araldite MY750 with hardener HY951). This resin shows greater integrity under electron beams than crystic resin. If, for some reason it is not possible to dry the sample then polyethylene glycol (PEG) is used, this is a waxy material which is soluble in water, has a low melting point and is reasonably easy to handle.

Processing of soil thin section slides involves the skilled manipulation of material bonded to glass slides to produce thin sections of around 30µm in thickness. These are then polished and coverslipped for protection.